OVER BAND MAGNETIC SEPARATORS

INTRODUCTION:

STAR TRACE SOLUTIONS PVT. LTD.’s Over band Magnetic Separator has been developed to handle high volume product stream flows that exceed the limitations of standard permanent suspended magnets. These models are available in both, manual on/off or automatic, self cleaning system designs. Electrical Power Supplies to operate the magnets are also available and recommended to ensure proper electrical power is supplied to the magnet.

CONSTRUCTION:

Two U-section pieces are fixed on the Magnet by fastening ears and are supporting bearings of Drums. Drums are equipped with shafts mounted on removable hubs. All bearings equipped with stakes for tightening the belt. The belt is driven by a Reduction Gear Coupled to Electric Motor or Geared Motor by Vee- belts.

Magnet Unit:

The Magnet is made of High Intensity Strontium Ferrite Magnets and is guaranteed for the Magnetic Power throughout the life of installation. A Non - Magnetic Stainless steel Plate is provided to cover the poles of Magnet. There is no need for any electrical supply or maintenance.

Applications

- Coal Industries

- Abrasive Industries

- Chemical Industries

- Paper and Pulp Industries

- Ceramic Industries

- Rubber Industries

- Petroleum Industries

- Animal Feed Industries

- Recycling Industries

- Mineral Processing

Features

- Permanent magnetic suspension separators are made with powerful Strontium Ferrite magnets.

- Special magnet features and options:

- 2-Pulley construction

- Totally-enclosed, removable dust-proof housings for self-cleaning magnets

- Heavy, wear-resistant manganese steel bottom plate

- Permanent magnet - no power required

- Most effective for removal of tramp iron from materials carried over conveyors/ vibratory feeders or inclined planes.

- Can be suspended for Longitudinal or Transversal cleaning over the conveyor belt.

- Available in widths from 16" to 90"

- Easy to install, without modifying existing lines

- In-line and cross-belt separators allow automatic discharge of collected tramp iron into suitable receptacles

- Rugged, 100% duty cycle design and construction

- Low maintenance, easy installation and operation

- Operates in hazardous environments

- High efficiency means energy cost savings

- Maintenance free

- Guaranteed performance

- Four point suspension

- Dust and rain protection

- Robust industrial Design

- Manufactured to customer specification

Specification:

- Permanent Magnetic Over band Separators are made with powerful Strontium Ferrite magnets and supplied for deep depth up to 300mm.

- Manufactured to suit conveyor width.

Specification 1

Technical Specification -1

- Permanent Magnetic Overband Separators are made with powerful Strontium Ferrite magnets and supplied for deep depth up to 300mm.

- Manufactured to suit conveyor width.

| DIMENSIONS AND TECHNICAL DATA | ||||||||

| Type | Belt Width mm | Working distance mm |

Weight kg | Drive KW | Overall dimensions | |||

| Across | Inline | Length | Width | Height | ||||

| OBMS-40/50-15 | 500 | 400 | 120-160 | 440 | 1,5 | 1380 | 1000 | 400 |

| OBMS-40/70-15 | 650 | 400 | 120-160 | 540 | 1,5 | 1580 | 1000 | 400 |

| OBMS-40/90-15 | 800 | 400 | 120-160 | 640 | 1,5 | 1780 | 1000 | 400 |

| OBMS-40/110-15 | 1000 | 400 | 120-160 | 740 | 1,5 | 1980 | 1000 | 400 |

| OBMS-60/50-20 | 500 | 650 | 170-220 | 640 | 1,5 | 1380 | 1200 | 400 |

| OBMS-60/70-20 | 650 | 650 | 170-220 | 780 | 1,5 | 1580 | 1200 | 400 |

| OBMS-60/90-20 | 800 | 650 | 170-220 | 920 | 1,5 | 1780 | 1200 | 400 |

| OBMS-60/110-20 | 1000 | 650 | 170-220 | 1060 | 1,5 | 1980 | 1200 | 400 |

| OBMS-60/130-20 | 1200 | 650 | 170-220 | 1220 | 1,5 | 2180 | 1200 | 400 |

| OBMS-75/70-25 | 650 | 800 | 220-270 | 1200 | 2,2 | 1830 | 1380 | 500 |

| OBMS-75/90-25 | 800 | 800 | 220-270 | 1340 | 2,2 | 2030 | 1380 | 500 |

| OBMS-75/110-25 | 1000 | 800 | 220-270 | 1660 | 2,2 | 2230 | 1380 | 500 |

| OBMS-75/130-25 | 1200 | 800 | 220-270 | 1800 | 2,2 | 2430 | 1380 | 500 |

| OBMS-75/150-25 | 1400 | 800 | 220-270 | 1940 | 2,2 | 2630 | 1380 | 500 |

| OBMS-95/70-30 | 650 | 1000 | 240-320 | 1430 | 2,2 | 1830 | 1580 | 500 |

| OBMS-95/90-30 | 800 | 1000 | 240-320 | 1650 | 2,2 | 2030 | 1580 | 500 |

| OBMS-95/110-30 | 1000 | 1000 | 240-320 | 1870 | 2,2 | 2230 | 1580 | 500 |

| OBMS-95/130-30 | 1200 | 1000 | 240-320 | 2100 | 2,2 | 2430 | 1580 | 500 |

| OBMS-95/150-30 | 1400 | 1000 | 240-320 | 2330 | 2,2 | 2630 | 1580 | 500 |

| OBMS-115/90-35 | 800 | 1200 | 260-350 | 2270 | 3,0 | 2030 | 1780 | 500 |

| OBMS-115/110-35 | 1000 | 1200 | 260-350 | 2250 | 3,0 | 2230 | 1780 | 500 |

| OBMS-115/130-35 | 1200 | 1200 | 260-350 | 2570 | 3,0 | 2430 | 1780 | 500 |

| OBMS-115/150-35 | 1400 | 1200 | 260-350 | 2900 | 3,0 | 2630 | 1780 | 500 |

| OBMS-130/110-35 | 1000 | 1400 | 280-370 | 2580 | 3,0 | 2230 | 1980 | 500 |

| OBMS-130/130-35 | 1200 | 1400 | 280-370 | 2950 | 3,0 | 2430 | 1980 | 500 |

| OBMS-130/150-35 | 1400 | 1400 | 280-370 | 3340 | 3,0 | 2630 | 1980 | 500 |

| OBMS-130/170-35 | 1600 | 1400 | 280-370 | 3750 | 3,0 | 2830 | 1980 | 500 |

| OBMS-150/130-40 | 1200 | 1600 | 300-390 | 3400 | 3,0 | 2430 | 2180 | 500 |

| OBMS-150/150-40 | 1400 | 1600 | 300-390 | 3840 | 3,0 | 2630 | 2180 | 500 |

| OBMS-150-170/40 | 1600 | 1600 | 300-390 | 4310 | 3,0 | 2830 | 2180 | 500 |

| OBMS-150-190/40 | 1800 | 1600 | 300-390 | 4810 | 3,0 | 3030 | 2180 | 500 |

Note:

- Technical data specification subject to change.

- Special OBMS can be made on request, Please send us your technical data and application, required for our engineers to provide.

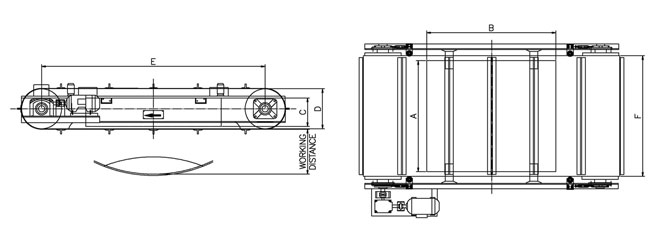

Technical Specification -2

| MAGNET DIMENSIONS | |||||

| a | b | c | d | e | f |

| 420 | 500 | 200 | 220 | 1110 | 470 |

| 420 | 700 | 200 | 220 | 1310 | 470 |

| 420 | 900 | 200 | 220 | 1510 | 470 |

| 420 | 1100 | 200 | 220 | 1710 | 470 |

| 620 | 500 | 200 | 220 | 1110 | 670 |

| 620 | 700 | 200 | 220 | 1310 | 670 |

| 620 | 900 | 200 | 220 | 1510 | 670 |

| 620 | 1100 | 200 | 220 | 1710 | 670 |

| 620 | 1300 | 200 | 220 | 1910 | 670 |

| 770 | 700 | 250 | 320 | 1450 | 830 |

| 770 | 900 | 250 | 320 | 1650 | 830 |

| 770 | 1100 | 250 | 320 | 1850 | 830 |

| 770 | 1300 | 250 | 320 | 2050 | 830 |

| 770 | 1500 | 250 | 320 | 2250 | 830 |

| 970 | 700 | 250 | 320 | 1450 | 1030 |

| 970 | 900 | 250 | 320 | 1650 | 1030 |

| 970 | 1100 | 250 | 320 | 1850 | 1030 |

| 970 | 1300 | 250 | 320 | 2050 | 1030 |

| 970 | 1500 | 250 | 320 | 2250 | 1030 |

| 1170 | 900 | 250 | 320 | 1650 | 1230 |

| 1170 | 1100 | 250 | 320 | 1850 | 1230 |

| 1170 | 1300 | 250 | 320 | 2050 | 1230 |

| 1170 | 1500 | 250 | 320 | 2250 | 1230 |

| 1370 | 1100 | 250 | 320 | 1850 | 1380 |

| 1370 | 1300 | 250 | 320 | 2050 | 1380 |

| 1370 | 1500 | 250 | 320 | 2250 | 1380 |

| 1370 | 1700 | 250 | 320 | 2450 | 1380 |

| 1520 | 1100 | 250 | 320 | 2050 | 1580 |

| 1520 | 1300 | 250 | 320 | 2250 | 1580 |

| 1520 | 1500 | 250 | 320 | 2450 | 1580 |

| 1520 | 1700 | 250 | 320 | 2650 | 1580 |

Note:

- Technical data specification subject to change.

- Special OBMS can be made on request, Please send us your technical data and application, required for our engineers to provide.